CUSTOM

JEWELRY EXPERIENCE

Our Promise

At Chawi Jewelers we pride ourselves on crafting custom jewelry to help make our customers’ dreams come to life. Our custom jewelry is made in-house by our master jeweler and his team. Every step is under strict scrutiny to ensure that our customer’s designs are produced to the highest possible quality. We at Chawi follow a detailed five-step production system allowing us to maintain a level of quality control that is only seen in our craftsmanship. Please follow us on a walkthrough of our five-step process.

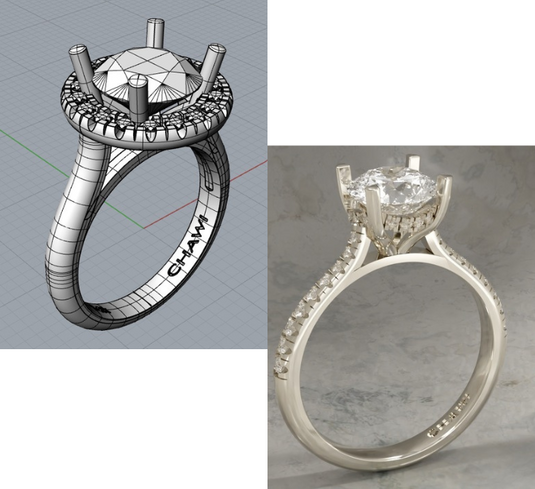

CAD and Rendering

We start by getting to know what our customer is looking for by talking to them either over the phone, or in our store. We then discuss what materials and gemstones the piece of jewelry is going to be made of. We work with any precious metals and gemstones you can think of. After getting a better idea of what our customer is looking for and what materials it will be made of, we start a rough sketch. Once the sketch, stone sizes, carat, and gold weight are finalized, we hand this over to our CAD designer. Our CAD specialist constructs a 3D model from the information, focusing on the structure of the custom piece. He then turns the 3D model into a realistic rendering, allowing you to see your jewelry before production. We adjust the rendering as needed, so your custom piece is exactly what you are looking for. After the rendering is approved, we start the first phase of production by 3D printing and casting.

3D Printing and Casting

We at Chawi not only want to produce the best quality jewelry for our customers but strive to create one of a kind heirloom pieces’ that will last a lifetime. We utilize state of the art high precision detailing 3D printers. These printers give us the ability to fine tune the details and intricacies of the piece. We upload your CAD file to our printer that will produce a wax model with every detail that you wanted. The wax is then encased in specialized clay and placed in a kiln to cook off, imprinting a cavity in which the jewelry will be cast. After the clay cools down, it is inspected to ensure there are no imperfections before the casting. The precious metal is carefully poured into the clay mold, marking the start if the 2nd stage of production.

Detailing / Assembly / Pre-polish

Casting is the phase in which your Jewelry idea is realized. Once complete, the piece begins to take form by being hand detailed, assembled, and a brief preliminary polishing. The raw cast will have sections that we cut by hand with a jeweler’s saw, which is followed by a lite filing to bring out more definition in the piece. We hand sand the entirety of the piece for a more uniformed look, this aids in the assembly portion of our process. Once sanding is complete, our master jeweler will assemble the piece. Each piece of jewelry is comprised of several parts, ensuring the structure is suitable for optimal durability and quality. Once assembled, the piece is inspected for any further precision detailing that may be needed. Following this last portion, it is ready for the Diamond setter to begin.

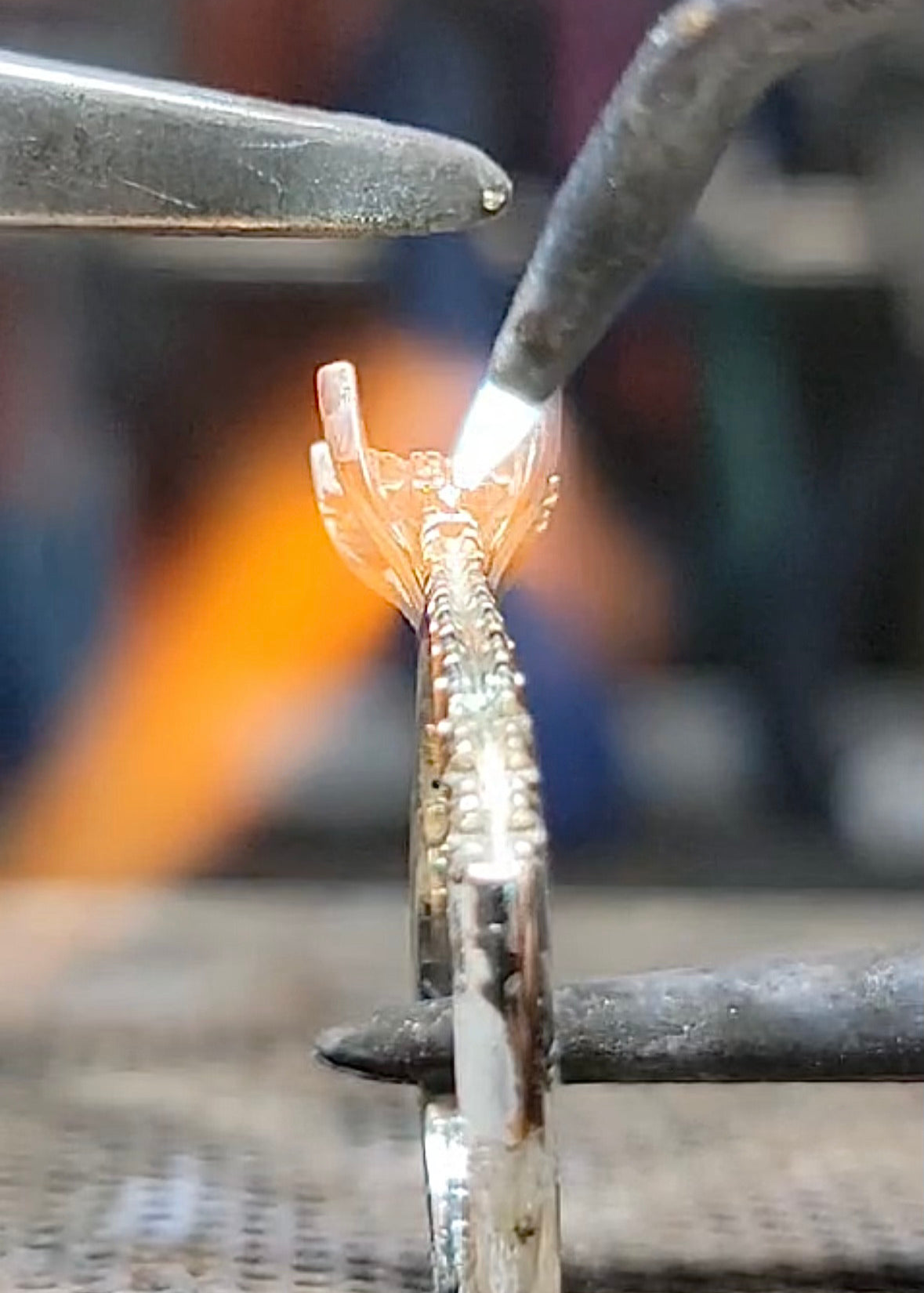

Stone/Diamond Setting

Diamond setting is the magnum opus of our custom process. Our Master Setter welcomes our customers to sit with him while their diamonds or stones are being set. We encourage photos, videos, and questions while you watch this process. The Diamond is placed in the crown (the basket that seats the stone on top of the ring) while the prongs are tightened around the stone, securing it into position. The Prongs are then filed and shaped to the proper size. All that remains is to use a cup graver to round the ends of the prongs, producing a smooth, de- burred area to help prevent sharp edges that can snag on clothing. After the setting is finished, we give the jewelry a gentle cleaning to be ready for final polishing.

Polishing/Rhodium finishing/cleaning

Our final step of custom jewelry at Chawi is hand polishing, Rhodium finishing for white gold pieces, and deep cleaning. Our expert polishers use a meticulous three step process to produce a shine that rivals a mirror finish. Starting with a rough wheel that takes out any surface scratches from the bench, followed by the medium wheel to smooth out the metal, and the third and final step is where the magic happens. The polishing wheel that is used, coupled with special rouge, can only be used by experts’ hands that have done this time and time again. The end result will capture any eye and be the center of the conversation wherever you go. We then place the jewelry in the ultra-sonic cleaner for about a hour to loosen any remaining debris from the crafting process before we hand brush and steam the piece for added clarity and elegance.

This is the Chawi Custom Jewelry and Experience that we guarantee with each custom piece of jewelry. Please give us a call or stop on by at our location in Danbury, Connecticut, we look forward to having a complimentary cup of coffee or an espresso and chatting with you.